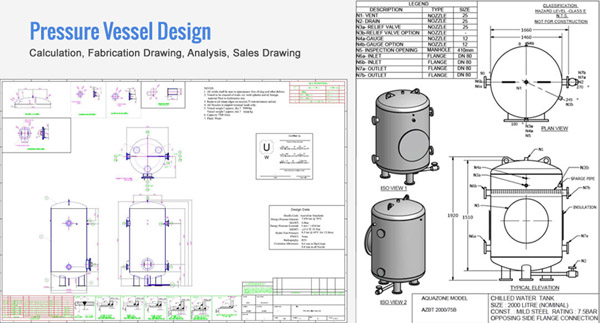

Pressure Vessel Design

Hi-Tech Export delivers comprehensive pressure vessels engineering and design services since several years. With the help of state-of-the-art computer technology, demonstrated machine engineering techniques, and ingenious creativeness shown by our designers.

We can create highly advanced pressure vessel design using AutoCAD, Inventor (3D Solid Modeling), and FEA (Finite Element Analysis). We have the aptitude of providing pressure equipment analysis and pressure vessel design & drawing services. We have professional team of CAD / CAE specialists for pressure vessel to improve the quality and efficiency of your product design management.

The ultimate objective of Hi-Tech Export is to generate pressure vessel designs that curb costs of production thereby enhancing production capacity.

Pressure Vessel Design Services:

- Pressure vessel design and analysis based on ASME Boiler & Pressure Vessel Code

- Analysis of Power Boilers as per ASME Boiler & Pressure Vessel Code, Section-1

- Calculations to check the suitability of vessels for in-situ PWHT

- Fatigue analysis to calculate the fatigue life of pressure vessels subjected to pressure cycles, temperature cycles and startup / shutdown cycles

- Failure Analysis to identify the root cause of failure for the failed pressure vessels or pressure vessel components

- Finite Element Analysis for pressure vessels and pressure vessel components

- Evaluation of cracks and Flaws in pressure vessels by applying Fracture Mechanics techniques

- Discontinuity Analysis for Pressure Vessels involving special situations of Structural and Material discontinuity

- Re-rating of pressure vessels for a new set of design parameters

- Calculation of minimum retirement thickness values for existing pressure vessels / pressure vessel components to maximize the remaining safe and useful life

- Design of Structural systems and supports for continued operation of leaked vessels or vessels that violate the minimum required thicknesses based on structural considerations

- Evaluation of Pressure Vessels after accidental over-pressurization

- Analysis to assure Mechanical Integrity of Pressure Vessels for following type of flaws: Generalized corrosion, Localized corrosion / Thinning, Blisters, Laminations, Bulges, Gouges, Dents, Cracks etc.

Upscale Differentiators:

- Our designers evaluate the precision of Pressure Vessels design before the ultimate finishing part of designing commences

- Unique combination of extensive industry experience along with practiced precision of pressure vessel design

- Assurance of high-end design, drafting and project management

- Detailed conferences with clients for high quality pressure vessels design requirements

- Pioneering knowledge of latest ASME pressure vessel fabrication methodology, technologies, codes and construction standards

Send your requirements related to pressure vessel design services to Hi-Tech Export.